Description

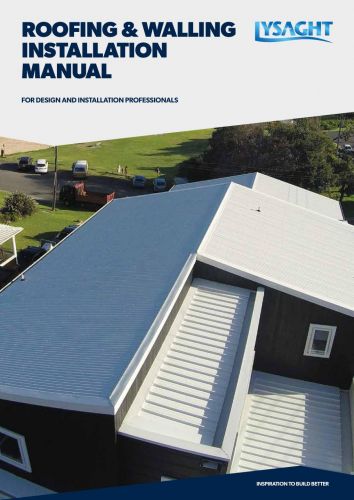

Clip fixed steel roofing or walling for supreme watertightness

Featuring a substantial, bold rib rising from wide, fluted pans, KLIP-LOK® creates a distinctive linear visual, uses a concealed fixing system and is ideally suited to near flat roof planes, including on large commercial & industrial buildings or on low pitched rooflines on residential buildings. KLIP-LOK®’s concealed fixing clips allow for superb watertightness.

Gallery

Profile Variants

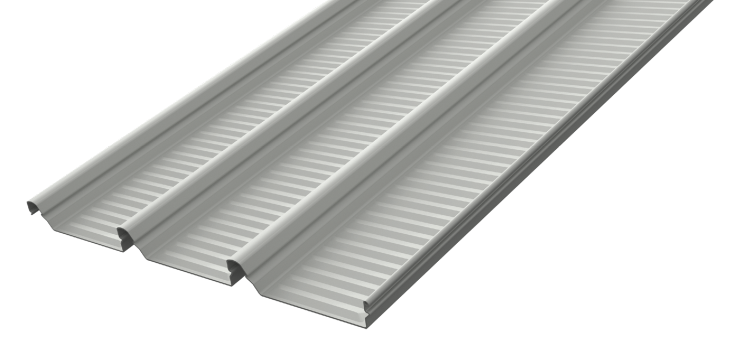

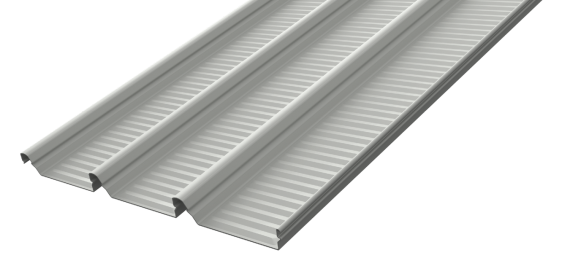

KLIP-LOK® 406

The KLIP-LOK® 406 features a narrower cover width and longitudinal fluting along the length of the pan, delivering precision-engineered results. This roof profile is designed for seamless integration with roofing and walling systems.

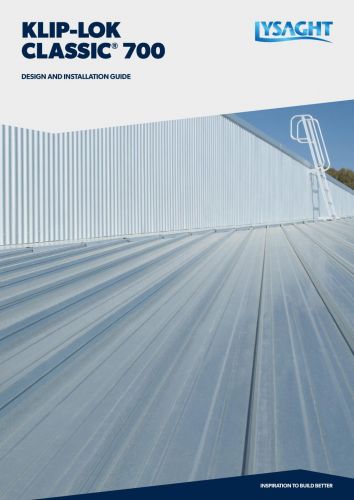

KLIP-LOK 700 CLASSIC®

The KLIP-LOK 700 CLASSIC® is an advanced roofing profile featuring longitudinal fluting along the length of the pan. Manufactured from COLORBOND® steel, it is ideal for metal roofing systems in commercial and residential buildings.

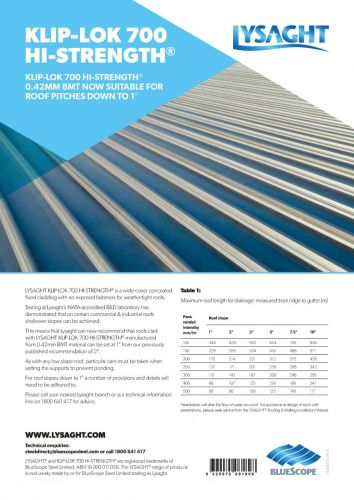

KLIP-LOK 700 HI-STRENGTH®

The KLIP-LOK 700 HI-STRENGTH® is an advanced roofing profile, offering either transverse fluting across the width or longitudinal fluting for enhanced performance and design versatility. Manufactured from COLORBOND® steel, it supports a wide range of architectural applications.

KLIP-LOK® 700NT Variant

The KLIP-LOK® 700 (NT Variant) is a specialised version featuring longitudinal fluting along the pan, manufactured specifically for projects in the Northern Territory. Its precise design ensures compatibility with various roofing profiles.

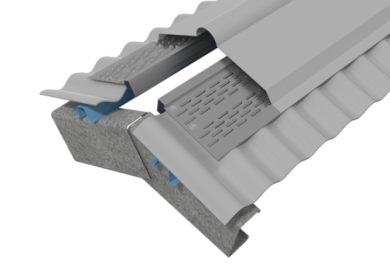

Systems & Solutions

The VENT-A-ROOF® passive ridge ventilation system enhances air circulation in roof cavities. Suitable for metal roofing in residential, commercial, and light industrial builds, it is compatible with CUSTOM ORB®, TRIMDEK®, KLIP-LOK 700 HI-STRENGTH®, and KLIP-LOK 700 CLASSIC® profiles.

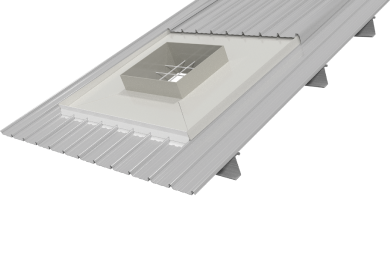

The POP-UP PENETRATION® system ensures even rainwater distribution around roof penetrations, preserving rainwater carrying capacity.

It is compatible with CUSTOM ORB®, TRIMDEK®, SPANDEK®, KLIP-LOK 700 HI-STRENGTH®, and KLIP-LOK 700 CLASSIC® profiles.

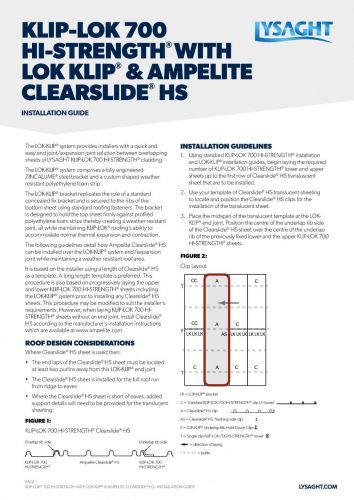

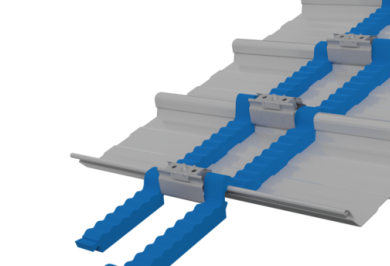

LOK-KLIP® & TRIM-KLIP®

• LOK-KLIP®: Designed for use with KLIP-LOK 700 HI-STRENGTH® and KLIP-LOK 700 CLASSIC®, it provides a fast and effective solution for weather-resistant end and expansion joints.

• TRIM-KLIP®: Compatible with TRIMDEK®, it offers reliable end joint sealing while maintaining uninterrupted rooflines.

On-site Manufacturing

Logistical challenges such as transportation limitations and site access restrictions no longer need to dictate design. Our relocatable mobile rollforming machine enables on-site manufacturing of KLIP-LOK 700 HI-STRENGTH®, allowing for long-length roof sheets to be formed directly at your project location. This minimises handling risks, streamlines installation, and ensures the integrity of your materials.

For more details on our mobile rollforming capabilities, please contact us.

Finishes & Colours

KLIP-LOK® is available in a wide range of colours and finishes, designed to complement modern and traditional architecture alike. Whether you’re looking for a bold statement rising above the skyline or a subtle, refined aesthetic, there’s a finish to match your vision.

All COLORBOND® steel and ZINCALUME® steel options are formulated for resilience, ensuring steel roofing that withstands Australia's tough weather conditions. Colour availability can vary by profile and location, so check with your supplier to confirm suitability for your project.

COLORBOND® Steel Colour Range

COLORBOND® Steel Colour Range

Core Colour Range

Core Colour Range

With 22 classic and contemporary colours, the COLORBOND® steel palette provides endless possibilities for personalisation. These finishes are designed for superior UV resistance and long-lasting vibrancy, making them an excellent choice for KLIP-LOK® roofs, where long straight lines and a sleek, modern aesthetic are key.

Ultra Colour Range

Ultra Colour Range

Engineered for harsh environments, this range delivers enhanced corrosion resistance while offering sleek, flat pan aesthetics perfect for KLIP-LOK® 700 HI-STRENGTH® installations in coastal and industrial areas. The combination of COLORBOND® Ultra steel and KLIP-LOK®'s concealed fixing ensures superior weathertight roofs in demanding conditions.

Matt Colour Range

Matt Colour Range

For a softer, modern look, the Matt finish introduces neutral tones that create a distinctive yet understated impact in roofing and wall applications.

Metallic Colour Range

Metallic Colour Range

Add a touch of brilliance with the Metallic Colour Range. Its strategically-placed particles create a long-lasting lustre, perfect for decorative finishes on walls, ceilings, and soffits that demand attention.

COOLMAX® Steel

COOLMAX® Steel

For projects prioritising thermal efficiency, COLORBOND® COOLMAX® steel provides the highest solar reflectance in the range, making it a smart pairing with KLIP-LOK®'s large-span roofing to help reduce cooling costs in commercial and industrial buildings.

COLORBOND® Steel Studio Library

For larger projects with specific colour requirements, COLORBOND® steel Studio offers over 200 colours, allowing precise matching by RGB, HEX values, or Dulux and RAL names. Minimum order quantities apply.

Unpainted Steel Range

Unpainted Steel Range

ZINCALUME® Steel

ZINCALUME® Steel

For a timeless, industrial-inspired look, MINI ORB® is also available in ZINCALUME® steel, combining a raw, unpainted aesthetic with exceptional corrosion resistance.

Get a brochure

GET AN E-BROCHURE